Foundry Sector

The foundry sector of Joban Seisakusho boasts a history since 1945, and has enriched its contents as the times have changed. Currently, we are melting and casting various products of gray cast iron (FC250 / 300) and ductile cast iron (FCD400 / 450/500/600). For molding, we have an automatic molding line and a furan self-hardening hand-made molding line, and we can produce heavy products up to 10 to 700 kg. The production capacity will be about 200t / month. The main uses of the product are automobile parts, construction machinery parts, hydraulic parts, etc.

Equipment of Foundry Sector

| Facility | Name and Capacity | Quantity | |

| Melting | High frequency electric furnace | 1.5t/B | 2 furnaces |

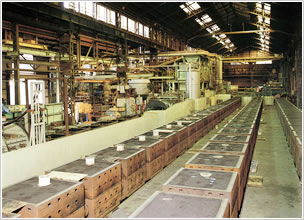

| Molding (includes Sand processing) | AMS-08 Machine molding line | 800 x 850 x 350 / 350 60s/cycle | 1 line |

| Furan bench molding line | 20t/month | 1 line | |

| Core making system | 2 sets | ||

| Machining | Overhead shot blast | 0.5t x 1set,2t x 1sets | 3 blasts |

| Drum-type shot blast | 1t/B | 2 blasts | |

| Compressor | 75kW | 3 compressors | |

| Shot blast machine | 3 blasts | ||

| Facility | Name and Capacity | Quantity | |

| Melting | High frequency electric furnace | 1.5t/B | 2 furnaces |

| Molding (includes Sand processing) | AMS-08 Machine molding line | 800 x 850 x 350 / 350 60s/cycle | 1 line |

| Furan bench molding line | 20t/month | 1 line | |

| Core making system | 2 sets | ||

| Machining | Overhead shot blast | 0.5t x 1set,2t x 1sets | 3 blasts |

| Drum-type shot blast | 1t/B | 2 blasts | |

| Compressor | 75kW | 3 compressors | |

| Shot blast machine | 3 blasts | ||

AMS-08 Machine molding line

AMS-08 Machine molding line

Furan bench molding line

Furan bench molding line

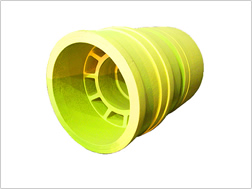

Foundry Product Samples

Product name:

Motor body

Material: FC300

Weight: 177kg

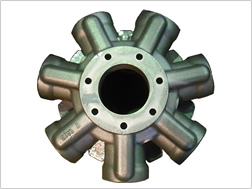

Product name:

Carrier B

Material: FCD450

Weight: 28.5kg

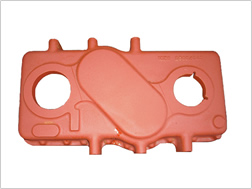

Product name:

Cover

Material: FC250

Weight: 50kg

Product name:

Hub

Material: FCD450

Weight: 560kg

Machining Sector

In 1938, one year after the foundry sector, the machinery plant of Joban Machinery Co., Ltd started running. The machinery plant has been operated broad production from the precision work for small parts to large parts for construction machines, and now the plant created the integrated manufacturing system including the assembly of hydraulic motors using our existing strength that we can make foundry materials on its own. Our hydraulic motor is used worldwide under the brand name of KYB Co., Ltd and is highly trusted. Of course, we are good at handling single parts.

Breakdown of Facilities in Machining Process Sector

| Facility No. | Facility | Quantity |

| 1 | Vertical Machining Center | 4 machines |

| 2 | Horizontal Machining Center | 14 machines |

| 3 | NC lathe | 16 machines |

| 4 | Lathe | 3 machines |

| 5 | Milling Machine | 2 machines |

| 6 | Honing Machine | 2 machines |

| 7 | Hobbing Machine | 2 machines |

| 8 | Drilling Machine | 5 machines |

| 9 | Polishing machine | 7 machines |

| 10 | Others | 33 machines |

| Total: | 89 machines |

Vertical Machining Center

NC lathe

Horizontal Machining Center

NC cylindrical grinder

NC inner width grinder

Automatic buffing machine

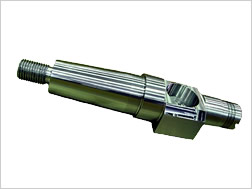

Machined products

Product name:

Motor body

Product name: Crankshaft

Product name:

Spacer

Product name:

Connecting rod

Quality-related Equipment

| Name | Quantity |

| Coordinate Measuring Machine | 1 |

| Roundness cylindrical shape measuring machine | 1 |

| Surface Roughness Tester | 1 |

| Contour Measuring | 1 |

| Optical Emission Spectrometer | 1 |

| Ultrasonic Flaw Detector | 1 |

| Amsler Universal Testing Machine | 1 |

| Charpy Impact Tester | 1 |

| Various Types of Hardness Scales | 6 |

| Various Types of Sand Testers | 7 |